平面变压器能使十分宝贵的印制电路板空间获得最大的利用

2003-01-02 15:00:54

来源:《国际电子变压器》2000.6

点击:1271

平面变压器能使十分宝贵的印制电路板空间获得最大的利用

Planar Transformers Make Maximum Use Of Precious Board Space

(小型、高密度平面变压器满足了电源越来越小的使用要求)

依赖于用铁氧体铁心和线绕绕组制作的体积较

大变压器的电源已经束缚了电子系统能达到的最小尺寸。经特殊设计的平面变压器可以缓解这一制约,并能满足在印制板的有限可供应用的空间安装所需的小尺寸要求。此外,采用这种结构能使变压器具有高功率密度容量、高频工作、高效率和多个重复一致性好的特色。其缺点几乎很少,因此掌握这类变压器的基本结构对全面了解其性能和可能出现的弊端是十分重要的。

1、无线设计

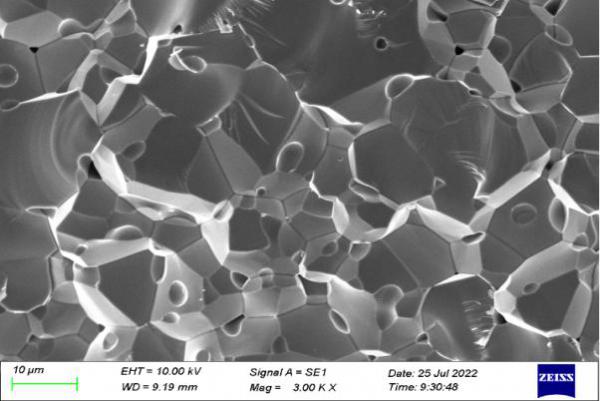

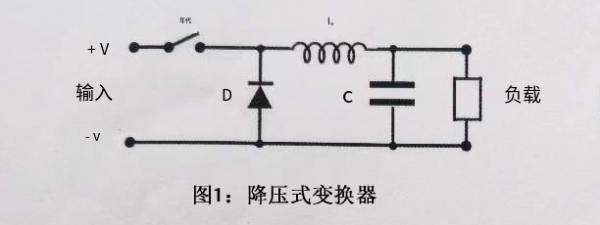

平面变压器能做到如此之小,这是因为它是由铜质引线框和扁平的连续铜质螺旋线构成,代替了在常规铁氧体铁心上绕制的磁性铜线,该螺旋线是在敷有铜箔的介质材料薄片上蚀刻而成,然后把它们叠积在扁平的高频铁氧体铁心上,构成变压器磁路(见图1)。

扁平的高频铁氧体铁心上,构成变压器磁路(见图1)。然后,铁心材料用小粒径环氧树脂粘合,以便使铁心损耗最小,螺旋线叠层内的耐高温(1300C)绝缘材料如聚酰亚胺薄膜确保了绕组之间的高度绝缘。虽然引线柜可被用来在物理上保证变压器在原安装的位置上(因该变压器重量很轻),而在高冲击的振动场合应用时,该扁平的铁氧体铁心能够用双面聚脂胶带粘贴在印制电路板上。该器件可通过标准的印制电路板引脚与外电路(如功率半导体电路)连接。

2、物理特性

上述结构的平面变压器具有尺寸小的特色,通常在0.325英寸到0.750英寸之间,这一特色对电源制造商在空间受到严格限制的场合具有相当的吸引力。

平面变压器印制电路板结构意指着一旦把电路板元件设定为平面器件,那么继后生产过程中的变压器绕组相互应具有精确的相同间距(见图2)。

这种设计就允许平面变压器用自动组装设备生产,结果大大提高了每个器件重复一致性,并提高了在严格技术规范控制下生产运行的效率。用常规铁氧体心绕铜导线制作的变压器由于绕组间隔不规则性和人工组装的不一致性都会导致器件性能有较大的差异。

此外,平面变压器的性能一致性和可预测性使它们具有建模比常规变压器更简易的优点,这尤其适于用计算机辅助(CAE)工具(如SPICE)建模。

在一般的电源设计中由于存在重量过重的问题,平面变压器能达到每100W0.6盎司这样低的重量,从而使它成了在许多轻重量电源设计中所选用的主要元件。

尽管平面变压器有好多好处,但在最初的开发中遇到了所需要的专用铁氧体心、印制电路板绕组和绝缘材料等难题,然而随着器件和材料性能达到可用水平,这种状况现在在发生变化。

3、电气特性

平面变压器在高的开关频率下能有效地工作,一般开关频率到500kHz时能达到97%的效率,它们的最高工作频率可达1MHz(在低磁通密度情况)。该变压器的高效率和高频工作特性的关键是扁平绕组,该绕组同时也能大大提高器件的功率密度容量。

由于常规变压器一般依赖于绕在铁氧体心上的圆导线绕组,因此铜导线的利用率不能得到充分利用,这是由于高频工作条件下电流趋肤效应所致。当感应电流如感应磁场在圆导线中引生电流,它们会集中在导线的外表层(或称趋肤),这种现象就是趋肤效应,尤其是较高工作频率下这种现象尤为明显。结果导致总的载流面积小于整个导线面积。使AC阻抗大于dc阻抗,其值取决于趋肤厚度。

在平面变压器中,其绕组实际上是在敷铜印制板上形成的一组扁平导电曲线,虽然由于趋肤效应电流集中趋向于外表层,但对它来说电流仍流经整个导线,这与圆柱(线型)导线相比提高了总的电流密度,最终,平面变压器由于采用了扁平绕组,与常规的线绕变压器相比能获较高的效率和更小的体积尺寸。

平面变压器结构还能使寄生电抗(如绕组间电容和漏感)最小,通常在0.5%以下。低漏感是通过分离措施实现的,就是把初级绕组一部分置于叠层的顶部,另一部置于叠层的底部,然后在叠层两边均匀地夹入次级绕组。

对线绕绕组来说,要控制漏感是困难的,平面变压器低的杂散电容和漏感很有利于降低变压器输出电压的高频瞬时扰动。采用在介质片上叠积导电电路这种结构还能使平面变压器的初级与次级和次级与次级之间达到很好的电绝缘,该变压器能适用宽范围的输入电压,并能按需要给于一个、二个或三个输出,它们也能满足或优于脱机转换器的性能要求。

4、平面电路的设计

由于载流能力在开关电源(SMPS)中是十分重要的,因此平面变压器在其内部绕组结构中通常采用4盎司敷铜电路板,同样级别的电路板对于开关电源的其它部分来说需要量是最少的。4盎司铜电路板所用的铜层的厚度为5.6密耳,即从中心到表面为2.8密耳。按圆导线计算,在温度700C时铜导线的电流趋肤深度可由下式求得:

式中,S是趋肤深度,以厘米为单位,f是工作频率。当工作频率为250kHz时算得的趋肤深度大致为5密耳,看来用4盎司的铜电路板还留有一些余量。

可是,需将4盎司平面铜电路截面转换成圆密耳(正如用导线表的情况一样),以便在给定的工作频率下对趋肤深度和电流密度作出更合理的检验。一圆密耳是直径为0.001英寸圆所占有的面积,这正好是将该面积的平方英寸数除以0.785x10-6。

在较大的电流密度(及较高的输出功率电平)场合,4盎司铜电路板可能会强度不足,所以多数电路板生产商会供应敷铜较厚的电路板,这通常是专门订购的。印制电路板也可采用并联方法,使电路尺寸倍增。

With Their Low Profile And High Density, Planar Devices Help Designers Meet Demands For Ever-Smaller Power Supplies

Power supplies have limited the minimum size that electronic systems can attain, relying as they do on large transformers with large ferrite cores and magnet wire windings. By their very design, planar transformers ease this limitation and allow designers to achieve the low profiles required for pc-board mounting in space-constrained applications . In addition, their construction endows them with more unit - to - unit repeatability, high power-density capability, higher - frequency operation, and high efficiency. While the disadvantages are few, it is important to understand the device’s basic construction to fully appreciate its capabilities and potential drawbacks.

Wire-Free Design

Planar transformers are so compact because they are made from copper leadframes and flat, continuous cop Power supplies have limited the minimum size that electronic systems can attain, relying as they do on large transformers with large ferrite cores and magnet wire windings. By their very design, planar transformers ease this limitation and allow designers to achieve the low profiles required for pc-board mounting in space-constrained applications . In addition, their construction endows them with more unit - to - unit repeatability, high power-density capability, higher - frequency operation, and high efficiency. While the disadvantages are few, it is important to understand the device’s basic construction to fully appreciate its capabilities and potential drawbacks.

Wire-Free Design

Planar transformers are so compact because they are made from copper leadframes and flat, continuous copper spirals instead of copper magnet wire wound around conventional ferrite cores. The spirals are etched on thin sheets of dielectric material and stacked on flat, high-frequency ferrite cores to form the transformer’s magnetic circuit(Fig.1). Next, the core material is bonded with a low-grain-diameter epoxy to minimize core losses. High-temperature(130oc)insulators, such as Kapton, within the stack of spirals ensure high isolation. between windings. While the leadframes are used to mechanically secure the transformer in place (because it is of low mass), for high-shock/vibration applications, the flat ferrite cores can be bonded to the pc-boxrd using double-sided polyester tape. Connections to the outside circuit, such as the power semiconductors, are made by standard pc-board pins.

Mechanical Features

It is this construction that gives the planar transformer its characteristically low profile, which usually ranges from between 0.325 to 0.750 in . This makes them especially attractive to power-supply manufacturers working within tight space restrictions.

The planar transformer’s pc-board construction means that once the circuit-board components are designed and stamped for a planar device, the windings of subsequent transformers in a production run will be spaced exactly the same distance from each other(Fig.2).This design allows planar transformers to be manufactured with automated assembly equipment, greatly improving device unit-to-unit repeatability and yield in production runs with tight specifi- cations. Conventional transformers are manufactured with copper wire wound arond ferrite cores. lrregularities in the spacing of the windings,along with the vagaries of manual assembly, can contrive to produce wide variations in device performance.

The uniformity and predictability of planar transformers has the added advantage of making them simpler to model than conventional transformers. This especially applies when using computer-aided-engineering(CAE)tools such as SPICE modeling.

With excess weight an on-going problem in the typical power-supply design, the planar’s ability to reach weihts an low as 0.6 oz.per 100W has made it a key component in many light-weight designs.

While the planar transformer has many advantages ,its development was initially hampered by the need for custom cores ,pc-board windings,and isolators.However,this attitude is changing as the devices gain acceptance.

Electrical Characteristics

Planar transformers offer efficient operation at high switching frequencies,typically reaching 97% efficiency at switching frequencies through 500kHz.Their maximum operating frequency can reach as high as 1 MHz (with low flux density).The flat windings are the key to their high efficiency and high-frequency operation.The windings also greatly improve the device’s power-density capabilities.

Because conventional transformers generally rely on round-wire windings around a ferrite core ,the copper conductor is not efficiently used. This is due to a phenomenon known as skin effect .Skin effect occurs when induced currents and magnetic fields cause current in a round conductor to concentrate near the thin outer surface - or skin - of the wire,especially at higher frequencies.As a re-sult ,the total current-carrying area is less than the full wire area, making the ac resistance greater than the dc resistance by an amount determined by the skin thickness.

In a planar transformer,however,the"windings"are actually flat conductive traces formed on copper-clad pc-boards.As a result,the current tends to concentrate toward the outer edges ,but it still flows through the entire conductor ,with improved overall current density compared to a cylindrical(wire)conductor. The end result is that a planar transformer ,with its flat windings,can achieve higher efficiency in much smaller sizes than conventional wire-wound transformers.

Planar construction also minimizes parasitic reactances, such as interwinding capacitance and leakage inductance (typically under 0.5%).The low leakage inductance is achieved by splitting,which puts part of the primary winding in one place,such as the top,part of the winding at the bottom of the stack,and then evenly sandwiching the secondary windings on both sides of the stack.

In wound designs ,leakage inductance is difficult to control.The low stray capacitances and leakage inductances go a long way toward reducing high-frequency ringing in a planar transformer’s output voltage.This construction-with conductive circuits stacked on dielectric sheets-also allows a planar transformer to achieve good primary-to-secondary and secondary-to-secondary dielectric isolation.The devices can accommodate a wide range of input voltrages,and can be specified with one,two,or three outputs.They also meet or exceed the performance requirements of offline converters.

Designing With Planars

Because current-carrying capability is a concern in an SMPS,planar transformers typically employ 4-oz.copperclad circuit boards for their internal winding forms,The same grade of circuit board is a minimum requirement for other sections of an SMPS.The copper used in a4-oz.copper circuit board is 5.6 mils thick,or2.8mils from the center to the surface.In a circular conductor,the current skin depth for copper at 700c can be obtained from the equation:

s=6.61 f

where S is the skin depth in centimeters, and fis the operating frequency.This works out to be a little over 5 mils at an operating frequency of 250kHz,It appears to leave little room for error with 4-oz.copper boards.

However, the planar cross section of 4-oz.copper must be converted to circular mils(as with wire tables)to make for a more meaningful examination of skin depth and currend density for a given operating frequency.A circular mil is the area occupied by a circle with the diameter of 0.001 in. Just divide the area in square inches by 0.785x10-6.

At higher current densities (and output power levels),4-oz.copper may not be robust enough.Most circuit-board manufacturers offer heavier copper cladding,usually as a special order. Pc-boards can also be paralleled to double the wire size.

simon Choina is a senior engineer with signal Transformer,speci

alizing in high-frequency devices.He received his electronic education in "Bosmath"by Technion in Haifa ,Israel,and finished his degree in New York city in 1986,He joined Signal in 1979 after three years with Power Magnetics.

Planar Transformers Make Maximum Use Of Precious Board Space

(小型、高密度平面变压器满足了电源越来越小的使用要求)

依赖于用铁氧体铁心和线绕绕组制作的体积较

大变压器的电源已经束缚了电子系统能达到的最小尺寸。经特殊设计的平面变压器可以缓解这一制约,并能满足在印制板的有限可供应用的空间安装所需的小尺寸要求。此外,采用这种结构能使变压器具有高功率密度容量、高频工作、高效率和多个重复一致性好的特色。其缺点几乎很少,因此掌握这类变压器的基本结构对全面了解其性能和可能出现的弊端是十分重要的。

1、无线设计

平面变压器能做到如此之小,这是因为它是由铜质引线框和扁平的连续铜质螺旋线构成,代替了在常规铁氧体铁心上绕制的磁性铜线,该螺旋线是在敷有铜箔的介质材料薄片上蚀刻而成,然后把它们叠积在扁平的高频铁氧体铁心上,构成变压器磁路(见图1)。

扁平的高频铁氧体铁心上,构成变压器磁路(见图1)。然后,铁心材料用小粒径环氧树脂粘合,以便使铁心损耗最小,螺旋线叠层内的耐高温(1300C)绝缘材料如聚酰亚胺薄膜确保了绕组之间的高度绝缘。虽然引线柜可被用来在物理上保证变压器在原安装的位置上(因该变压器重量很轻),而在高冲击的振动场合应用时,该扁平的铁氧体铁心能够用双面聚脂胶带粘贴在印制电路板上。该器件可通过标准的印制电路板引脚与外电路(如功率半导体电路)连接。

2、物理特性

上述结构的平面变压器具有尺寸小的特色,通常在0.325英寸到0.750英寸之间,这一特色对电源制造商在空间受到严格限制的场合具有相当的吸引力。

平面变压器印制电路板结构意指着一旦把电路板元件设定为平面器件,那么继后生产过程中的变压器绕组相互应具有精确的相同间距(见图2)。

这种设计就允许平面变压器用自动组装设备生产,结果大大提高了每个器件重复一致性,并提高了在严格技术规范控制下生产运行的效率。用常规铁氧体心绕铜导线制作的变压器由于绕组间隔不规则性和人工组装的不一致性都会导致器件性能有较大的差异。

此外,平面变压器的性能一致性和可预测性使它们具有建模比常规变压器更简易的优点,这尤其适于用计算机辅助(CAE)工具(如SPICE)建模。

在一般的电源设计中由于存在重量过重的问题,平面变压器能达到每100W0.6盎司这样低的重量,从而使它成了在许多轻重量电源设计中所选用的主要元件。

尽管平面变压器有好多好处,但在最初的开发中遇到了所需要的专用铁氧体心、印制电路板绕组和绝缘材料等难题,然而随着器件和材料性能达到可用水平,这种状况现在在发生变化。

3、电气特性

平面变压器在高的开关频率下能有效地工作,一般开关频率到500kHz时能达到97%的效率,它们的最高工作频率可达1MHz(在低磁通密度情况)。该变压器的高效率和高频工作特性的关键是扁平绕组,该绕组同时也能大大提高器件的功率密度容量。

由于常规变压器一般依赖于绕在铁氧体心上的圆导线绕组,因此铜导线的利用率不能得到充分利用,这是由于高频工作条件下电流趋肤效应所致。当感应电流如感应磁场在圆导线中引生电流,它们会集中在导线的外表层(或称趋肤),这种现象就是趋肤效应,尤其是较高工作频率下这种现象尤为明显。结果导致总的载流面积小于整个导线面积。使AC阻抗大于dc阻抗,其值取决于趋肤厚度。

在平面变压器中,其绕组实际上是在敷铜印制板上形成的一组扁平导电曲线,虽然由于趋肤效应电流集中趋向于外表层,但对它来说电流仍流经整个导线,这与圆柱(线型)导线相比提高了总的电流密度,最终,平面变压器由于采用了扁平绕组,与常规的线绕变压器相比能获较高的效率和更小的体积尺寸。

平面变压器结构还能使寄生电抗(如绕组间电容和漏感)最小,通常在0.5%以下。低漏感是通过分离措施实现的,就是把初级绕组一部分置于叠层的顶部,另一部置于叠层的底部,然后在叠层两边均匀地夹入次级绕组。

对线绕绕组来说,要控制漏感是困难的,平面变压器低的杂散电容和漏感很有利于降低变压器输出电压的高频瞬时扰动。采用在介质片上叠积导电电路这种结构还能使平面变压器的初级与次级和次级与次级之间达到很好的电绝缘,该变压器能适用宽范围的输入电压,并能按需要给于一个、二个或三个输出,它们也能满足或优于脱机转换器的性能要求。

4、平面电路的设计

由于载流能力在开关电源(SMPS)中是十分重要的,因此平面变压器在其内部绕组结构中通常采用4盎司敷铜电路板,同样级别的电路板对于开关电源的其它部分来说需要量是最少的。4盎司铜电路板所用的铜层的厚度为5.6密耳,即从中心到表面为2.8密耳。按圆导线计算,在温度700C时铜导线的电流趋肤深度可由下式求得:

式中,S是趋肤深度,以厘米为单位,f是工作频率。当工作频率为250kHz时算得的趋肤深度大致为5密耳,看来用4盎司的铜电路板还留有一些余量。

可是,需将4盎司平面铜电路截面转换成圆密耳(正如用导线表的情况一样),以便在给定的工作频率下对趋肤深度和电流密度作出更合理的检验。一圆密耳是直径为0.001英寸圆所占有的面积,这正好是将该面积的平方英寸数除以0.785x10-6。

在较大的电流密度(及较高的输出功率电平)场合,4盎司铜电路板可能会强度不足,所以多数电路板生产商会供应敷铜较厚的电路板,这通常是专门订购的。印制电路板也可采用并联方法,使电路尺寸倍增。

With Their Low Profile And High Density, Planar Devices Help Designers Meet Demands For Ever-Smaller Power Supplies

Power supplies have limited the minimum size that electronic systems can attain, relying as they do on large transformers with large ferrite cores and magnet wire windings. By their very design, planar transformers ease this limitation and allow designers to achieve the low profiles required for pc-board mounting in space-constrained applications . In addition, their construction endows them with more unit - to - unit repeatability, high power-density capability, higher - frequency operation, and high efficiency. While the disadvantages are few, it is important to understand the device’s basic construction to fully appreciate its capabilities and potential drawbacks.

Wire-Free Design

Planar transformers are so compact because they are made from copper leadframes and flat, continuous cop Power supplies have limited the minimum size that electronic systems can attain, relying as they do on large transformers with large ferrite cores and magnet wire windings. By their very design, planar transformers ease this limitation and allow designers to achieve the low profiles required for pc-board mounting in space-constrained applications . In addition, their construction endows them with more unit - to - unit repeatability, high power-density capability, higher - frequency operation, and high efficiency. While the disadvantages are few, it is important to understand the device’s basic construction to fully appreciate its capabilities and potential drawbacks.

Wire-Free Design

Planar transformers are so compact because they are made from copper leadframes and flat, continuous copper spirals instead of copper magnet wire wound around conventional ferrite cores. The spirals are etched on thin sheets of dielectric material and stacked on flat, high-frequency ferrite cores to form the transformer’s magnetic circuit(Fig.1). Next, the core material is bonded with a low-grain-diameter epoxy to minimize core losses. High-temperature(130oc)insulators, such as Kapton, within the stack of spirals ensure high isolation. between windings. While the leadframes are used to mechanically secure the transformer in place (because it is of low mass), for high-shock/vibration applications, the flat ferrite cores can be bonded to the pc-boxrd using double-sided polyester tape. Connections to the outside circuit, such as the power semiconductors, are made by standard pc-board pins.

Mechanical Features

It is this construction that gives the planar transformer its characteristically low profile, which usually ranges from between 0.325 to 0.750 in . This makes them especially attractive to power-supply manufacturers working within tight space restrictions.

The planar transformer’s pc-board construction means that once the circuit-board components are designed and stamped for a planar device, the windings of subsequent transformers in a production run will be spaced exactly the same distance from each other(Fig.2).This design allows planar transformers to be manufactured with automated assembly equipment, greatly improving device unit-to-unit repeatability and yield in production runs with tight specifi- cations. Conventional transformers are manufactured with copper wire wound arond ferrite cores. lrregularities in the spacing of the windings,along with the vagaries of manual assembly, can contrive to produce wide variations in device performance.

The uniformity and predictability of planar transformers has the added advantage of making them simpler to model than conventional transformers. This especially applies when using computer-aided-engineering(CAE)tools such as SPICE modeling.

With excess weight an on-going problem in the typical power-supply design, the planar’s ability to reach weihts an low as 0.6 oz.per 100W has made it a key component in many light-weight designs.

While the planar transformer has many advantages ,its development was initially hampered by the need for custom cores ,pc-board windings,and isolators.However,this attitude is changing as the devices gain acceptance.

Electrical Characteristics

Planar transformers offer efficient operation at high switching frequencies,typically reaching 97% efficiency at switching frequencies through 500kHz.Their maximum operating frequency can reach as high as 1 MHz (with low flux density).The flat windings are the key to their high efficiency and high-frequency operation.The windings also greatly improve the device’s power-density capabilities.

Because conventional transformers generally rely on round-wire windings around a ferrite core ,the copper conductor is not efficiently used. This is due to a phenomenon known as skin effect .Skin effect occurs when induced currents and magnetic fields cause current in a round conductor to concentrate near the thin outer surface - or skin - of the wire,especially at higher frequencies.As a re-sult ,the total current-carrying area is less than the full wire area, making the ac resistance greater than the dc resistance by an amount determined by the skin thickness.

In a planar transformer,however,the"windings"are actually flat conductive traces formed on copper-clad pc-boards.As a result,the current tends to concentrate toward the outer edges ,but it still flows through the entire conductor ,with improved overall current density compared to a cylindrical(wire)conductor. The end result is that a planar transformer ,with its flat windings,can achieve higher efficiency in much smaller sizes than conventional wire-wound transformers.

Planar construction also minimizes parasitic reactances, such as interwinding capacitance and leakage inductance (typically under 0.5%).The low leakage inductance is achieved by splitting,which puts part of the primary winding in one place,such as the top,part of the winding at the bottom of the stack,and then evenly sandwiching the secondary windings on both sides of the stack.

In wound designs ,leakage inductance is difficult to control.The low stray capacitances and leakage inductances go a long way toward reducing high-frequency ringing in a planar transformer’s output voltage.This construction-with conductive circuits stacked on dielectric sheets-also allows a planar transformer to achieve good primary-to-secondary and secondary-to-secondary dielectric isolation.The devices can accommodate a wide range of input voltrages,and can be specified with one,two,or three outputs.They also meet or exceed the performance requirements of offline converters.

Designing With Planars

Because current-carrying capability is a concern in an SMPS,planar transformers typically employ 4-oz.copperclad circuit boards for their internal winding forms,The same grade of circuit board is a minimum requirement for other sections of an SMPS.The copper used in a4-oz.copper circuit board is 5.6 mils thick,or2.8mils from the center to the surface.In a circular conductor,the current skin depth for copper at 700c can be obtained from the equation:

s=6.61 f

where S is the skin depth in centimeters, and fis the operating frequency.This works out to be a little over 5 mils at an operating frequency of 250kHz,It appears to leave little room for error with 4-oz.copper boards.

However, the planar cross section of 4-oz.copper must be converted to circular mils(as with wire tables)to make for a more meaningful examination of skin depth and currend density for a given operating frequency.A circular mil is the area occupied by a circle with the diameter of 0.001 in. Just divide the area in square inches by 0.785x10-6.

At higher current densities (and output power levels),4-oz.copper may not be robust enough.Most circuit-board manufacturers offer heavier copper cladding,usually as a special order. Pc-boards can also be paralleled to double the wire size.

simon Choina is a senior engineer with signal Transformer,speci

alizing in high-frequency devices.He received his electronic education in "Bosmath"by Technion in Haifa ,Israel,and finished his degree in New York city in 1986,He joined Signal in 1979 after three years with Power Magnetics.

暂无评论